In essence six sigma seeks to – In essence, Six Sigma seeks to improve quality and efficiency by identifying and eliminating defects and waste in business processes. It is a data-driven approach that uses statistical analysis and other tools to identify and eliminate the root causes of problems.

Six Sigma has been successfully applied in a wide range of industries, including manufacturing, healthcare, and finance.

The key principles of Six Sigma include:

- Define the problem or opportunity.

- Measure the current process.

- Analyze the data to identify the root causes of the problem.

- Improve the process by eliminating the root causes.

- Control the process to ensure that the improvements are sustained.

Definition of Six Sigma

Six Sigma is a quality management methodology that aims to eliminate defects and improve business processes. It was developed by Motorola in the 1980s and has since been adopted by many organizations worldwide.Six Sigma uses a data-driven approach to identify and eliminate sources of variation in a process.

The goal is to achieve a level of performance where only 3.4 defects occur per million opportunities (DPMO). This level of quality is known as “six sigma.”

Origins of Six Sigma

The origins of Six Sigma can be traced back to the work of Walter Shewhart, a statistician who developed the concept of statistical process control (SPC) in the 1920s. SPC is a method for using statistical techniques to monitor and control processes.In

the 1980s, Motorola adapted SPC to create Six Sigma. Motorola’s goal was to improve the quality of its products and reduce costs. Six Sigma quickly became a success at Motorola, and other organizations soon began to adopt the methodology.

Applications of Six Sigma

Six Sigma has been applied in a wide variety of industries, including manufacturing, healthcare, and financial services. Some examples of how Six Sigma has been used include:

- Reducing defects in manufacturing processes

- Improving patient safety in hospitals

- Reducing costs in financial institutions

Key Principles of Six Sigma

Six Sigma employs a set of principles to guide its approach to process improvement. These principles are designed to provide a structured and systematic framework for identifying, analyzing, and eliminating defects and variations in processes. The five key principles of Six Sigma are:

- DMAIC(Define, Measure, Analyze, Improve, Control): DMAIC is a five-step problem-solving methodology used to improve existing processes. It involves defining the problem, measuring the current performance, analyzing the data to identify root causes, implementing improvements, and controlling the process to ensure sustained improvements.

- DMADV(Define, Measure, Analyze, Design, Verify): DMADV is a five-step methodology used to design and develop new processes or products. It involves defining the customer requirements, measuring the current performance, analyzing the data to identify opportunities for improvement, designing the new process or product, and verifying its performance.

- DFSS(Design for Six Sigma): DFSS is a methodology used to design and develop products and processes that meet Six Sigma quality standards from the outset. It involves using statistical techniques to optimize the design and eliminate potential defects.

- PDCA(Plan, Do, Check, Act): PDCA is a four-step problem-solving cycle used to continuously improve processes. It involves planning the improvement, implementing the plan, checking the results, and acting to make further improvements.

- TRIZ(Theory of Inventive Problem Solving): TRIZ is a problem-solving methodology that uses a database of known solutions to identify and overcome common problems. It involves identifying the root cause of the problem, searching the database for similar solutions, and adapting the solutions to the specific problem at hand.

Benefits of Six Sigma

Six Sigma offers a plethora of benefits to organizations that implement its principles and methodologies. By focusing on process improvement and defect reduction, Six Sigma can lead to significant improvements in quality, cost reduction, and overall efficiency.

Numerous case studies and examples demonstrate the tangible benefits of Six Sigma implementation. For instance, Motorola, a pioneer in Six Sigma, reduced its defects by 99%, resulting in billions of dollars in savings.

Improved Quality

Six Sigma’s focus on defect reduction and process improvement directly translates to enhanced product or service quality. By identifying and eliminating sources of errors and inefficiencies, organizations can deliver products or services that meet or exceed customer expectations.

Reduced Costs

Six Sigma’s emphasis on waste reduction and efficiency improvement leads to significant cost savings. By eliminating defects and streamlining processes, organizations can reduce production costs, improve productivity, and minimize waste.

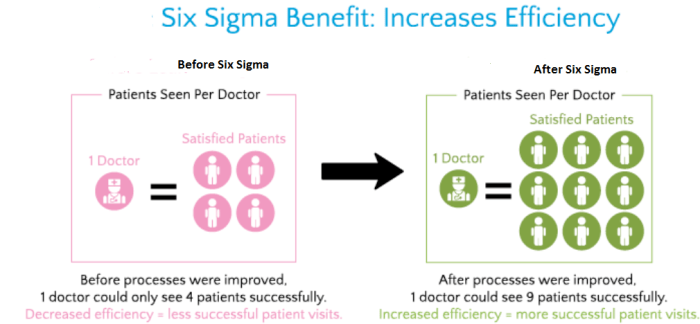

Increased Efficiency

Six Sigma promotes process optimization and standardization, which can result in increased efficiency across the organization. By identifying bottlenecks and inefficiencies, organizations can streamline their operations, improve cycle times, and enhance overall productivity.

Six Sigma Tools and Techniques

Six Sigma employs a comprehensive suite of tools and techniques to drive continuous improvement and optimize processes. These tools provide a structured approach to problem-solving, enabling teams to identify and eliminate root causes of variation and defects.

Statistical Analysis

Statistical analysis is a cornerstone of Six Sigma, providing insights into process performance and variation. Tools such as control charts, histograms, and statistical process control (SPC) help teams monitor and analyze data to identify trends, outliers, and areas for improvement.

In essence, Six Sigma seeks to eliminate defects and improve processes. Take the element with 61 neutrons, what element has 61 neutrons ? By understanding its properties and behavior, Six Sigma can help optimize processes involving this element, leading to improved quality and efficiency.

For instance, a manufacturing process may use control charts to track product dimensions. If the chart shows a pattern of variation exceeding acceptable limits, the team can investigate potential causes and implement corrective actions to bring the process back within control.

Process Mapping

Process mapping visually depicts the flow of a process, identifying key steps, inputs, outputs, and decision points. It helps teams understand the process, identify bottlenecks, and optimize the sequence of activities.

In a customer service process, process mapping can reveal areas where delays or inefficiencies occur. By analyzing the map, the team can redesign the process to streamline operations and improve customer satisfaction.

Root Cause Analysis

Root cause analysis delves into the underlying factors that contribute to a problem or defect. Tools such as fishbone diagrams and 5 Whys help teams systematically identify and address the root causes, rather than just treating symptoms.

For example, a company experiencing high customer churn rates may use a fishbone diagram to identify potential causes such as poor product quality, ineffective marketing, or inefficient customer service. By addressing the root causes, the company can develop sustainable solutions to reduce churn.

Implementation of Six Sigma

The successful implementation of Six Sigma within an organization requires a structured approach and a commitment from all levels of management. It typically involves the following steps:

Planning, In essence six sigma seeks to

Define the goals and objectives of the Six Sigma initiative. Identify the processes that need improvement and establish a baseline for measuring progress.

Training

Train employees in Six Sigma methodologies and tools. This includes training in statistical analysis, process improvement techniques, and project management.

Project Selection

Select high-impact projects that align with the organization’s goals. These projects should have a clear scope and timeline.

Project Execution

Implement Six Sigma methodologies to improve the selected processes. This includes using tools such as DMAIC (Define, Measure, Analyze, Improve, Control) and Lean principles.

Evaluation and Monitoring

Track the progress of Six Sigma projects and evaluate their impact. Make necessary adjustments to the implementation plan based on the results.

Challenges and Considerations

Implementing Six Sigma can be challenging. Some common challenges include:

- Resistance to change from employees

- Lack of understanding of Six Sigma methodologies

- Insufficient resources or support

- Unrealistic expectations or timelines

To address these challenges, organizations should:

- Provide clear communication and training to employees

- Secure buy-in from senior management

- Allocate adequate resources and support

- Set realistic goals and timelines

Role of Leadership in Six Sigma: In Essence Six Sigma Seeks To

Leadership plays a pivotal role in driving successful Six Sigma initiatives. Leaders are responsible for creating a culture that supports and encourages Six Sigma principles. They must demonstrate a commitment to quality and continuous improvement, and they must provide the necessary resources and support to ensure that Six Sigma projects are successful.

Responsibilities and Expectations of Leaders in Supporting Six Sigma Implementation

- Create a clear vision and strategy for Six Sigma implementation.

- Communicate the vision and strategy to all stakeholders.

- Provide the necessary resources and support to Six Sigma teams.

- Remove barriers to Six Sigma implementation.

- Celebrate successes and learn from failures.

Training and Certification in Six Sigma

Six Sigma training and certification programs equip individuals with the knowledge and skills necessary to implement Six Sigma methodologies in their organizations. These programs offer various levels of certification, each with specific requirements and benefits.

Certification Levels

- White Belt:Introductory level, providing a basic understanding of Six Sigma principles and tools.

- Yellow Belt:Intermediate level, focusing on project selection, data collection, and basic statistical analysis.

- Green Belt:Advanced level, enabling individuals to lead small-scale Six Sigma projects and apply statistical techniques.

- Black Belt:Expert level, responsible for managing large-scale projects and training others in Six Sigma.

- Master Black Belt:Senior level, providing strategic guidance and oversight for Six Sigma initiatives.

Benefits of Certification

For Individuals:

- Enhanced career prospects in quality management, process improvement, and data analytics.

- Improved problem-solving and analytical skills.

- Increased credibility and recognition in the industry.

For Organizations:

- Improved process efficiency and reduced costs.

- Enhanced customer satisfaction and loyalty.

- Increased employee engagement and motivation.

Six Sigma in the Modern Workplace

Six Sigma has evolved significantly in the modern workplace, adapting to the rapid advancements in technology and data analytics. Digital technologies have revolutionized the way organizations collect, analyze, and interpret data, providing unprecedented opportunities for Six Sigma practitioners to drive innovation and continuous improvement.

Integration of Digital Technologies

The integration of digital technologies has enabled Six Sigma teams to automate many aspects of the improvement process, from data collection and analysis to project management and reporting. This automation has freed up time for Six Sigma practitioners to focus on more strategic initiatives, such as developing innovative solutions and identifying new opportunities for improvement.

Data Analytics and Predictive Modeling

Data analytics and predictive modeling have become essential tools for Six Sigma practitioners. By leveraging advanced statistical techniques and machine learning algorithms, Six Sigma teams can identify patterns and trends in data that would otherwise be invisible to the naked eye.

This enables them to make more informed decisions, predict future outcomes, and proactively identify and mitigate risks.

Examples of Six Sigma in the Modern Workplace

- A manufacturing company used Six Sigma to optimize its production process, reducing defects by 50% and increasing productivity by 20%.

- A healthcare provider used Six Sigma to improve patient satisfaction by 15% and reduce hospital readmission rates by 10%.

- A financial services company used Six Sigma to develop a new fraud detection system that reduced losses by 25%.

FAQ Guide

What is Six Sigma?

Six Sigma is a data-driven approach to improving quality and efficiency by identifying and eliminating defects and waste in business processes.

What are the benefits of Six Sigma?

Six Sigma can help organizations to improve quality, reduce costs, and increase efficiency.

How is Six Sigma implemented?

Six Sigma is implemented using a five-step process called DMAIC (Define, Measure, Analyze, Improve, Control).